PCB Manufacturing

-

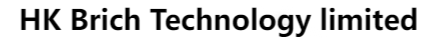

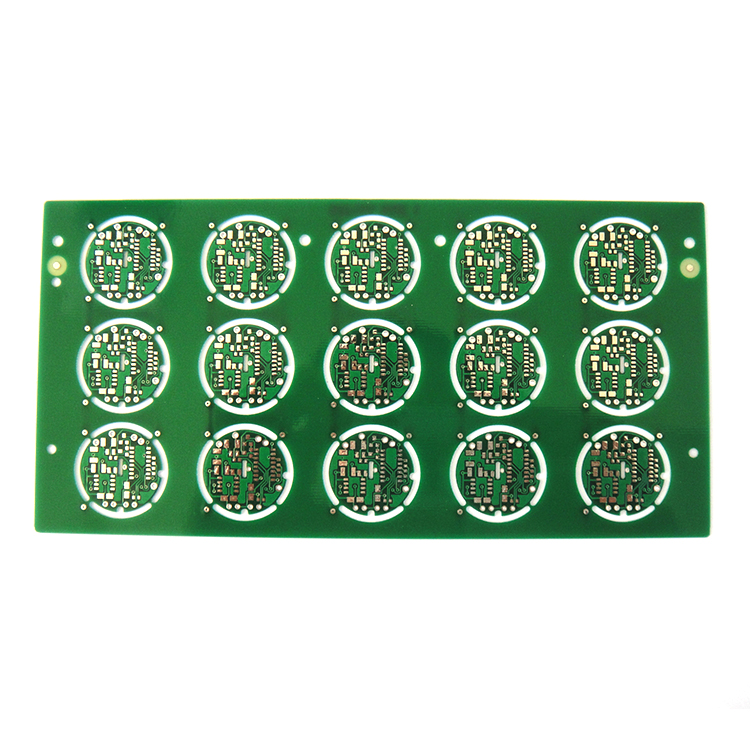

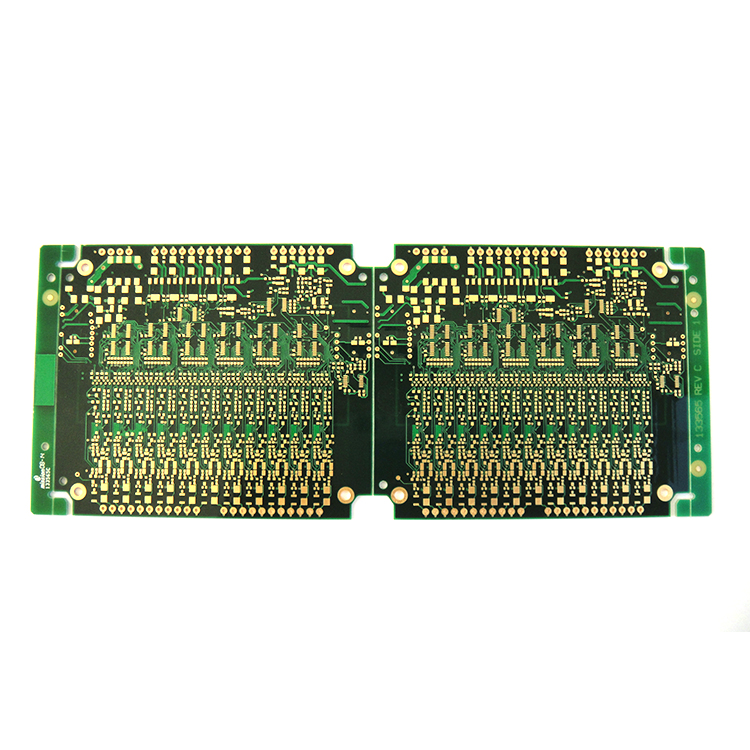

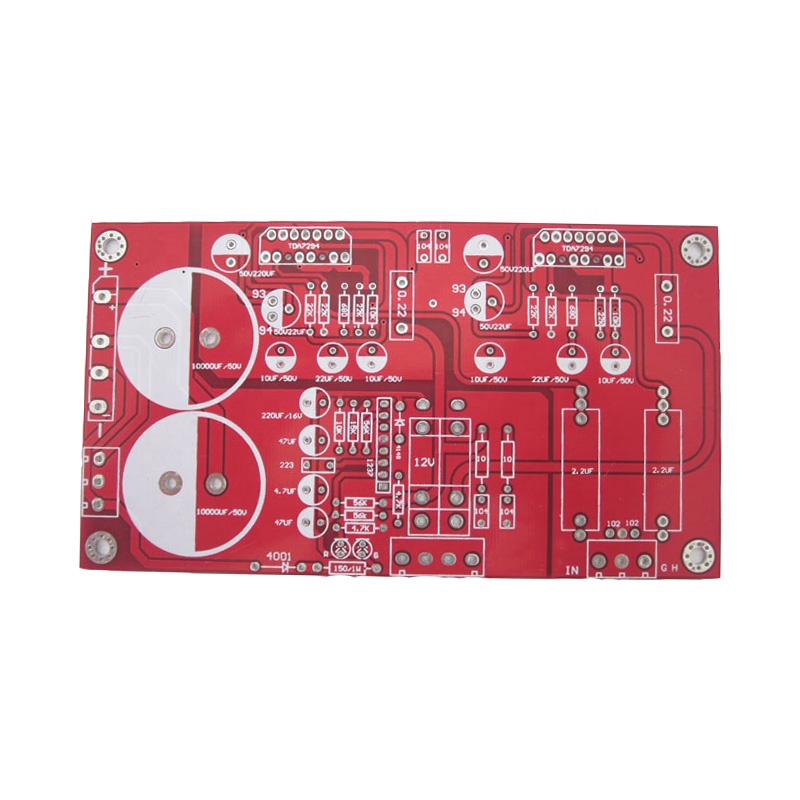

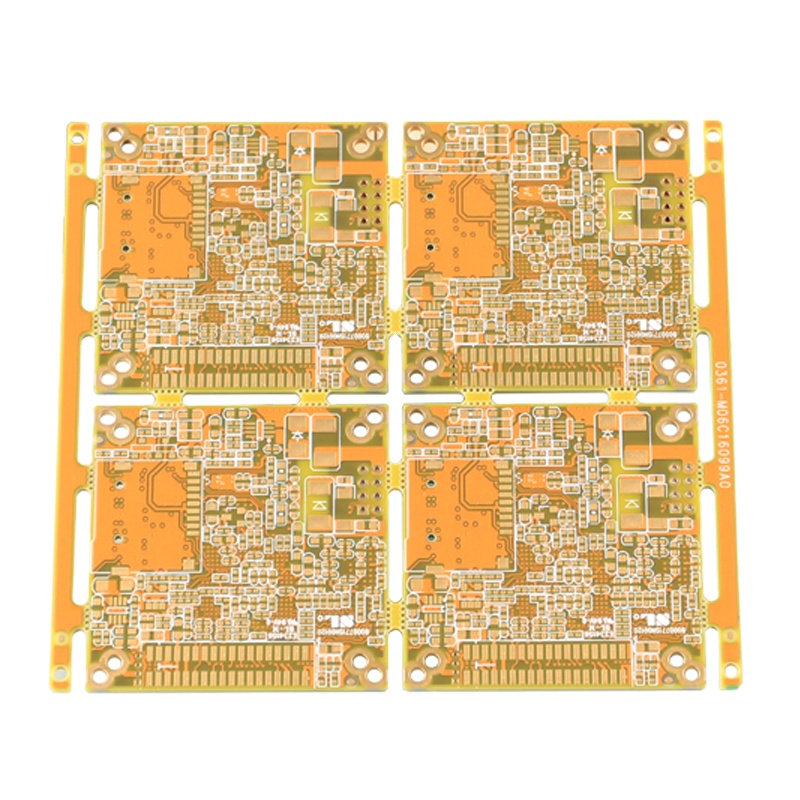

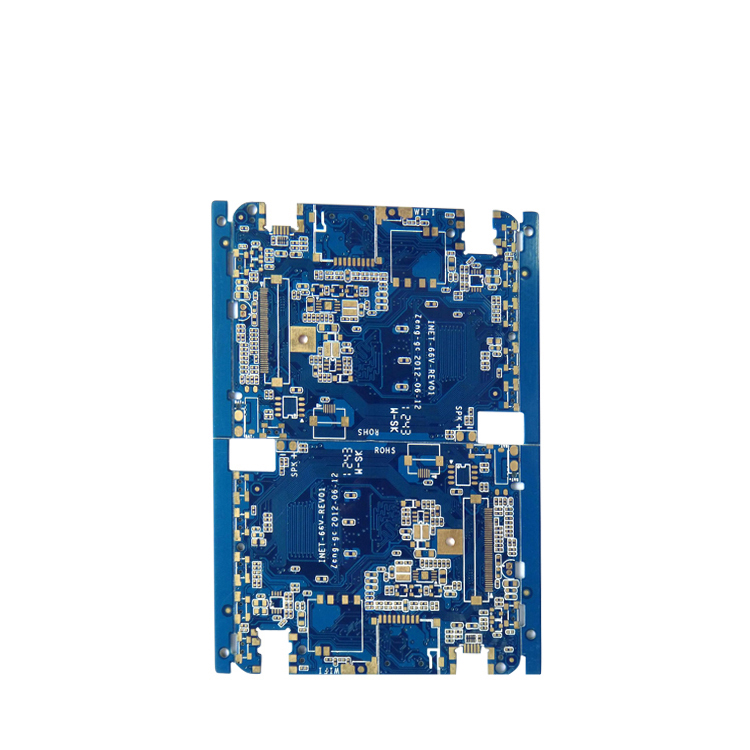

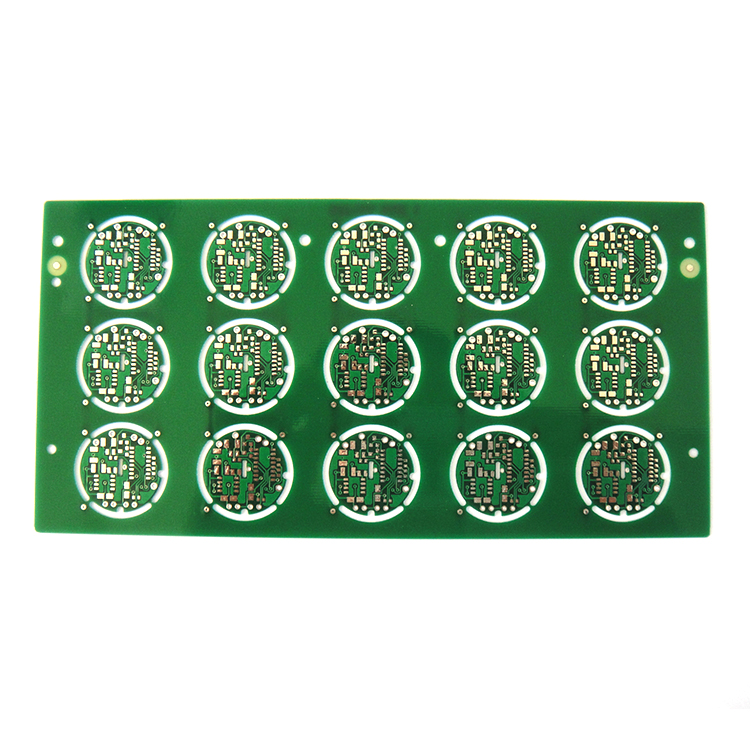

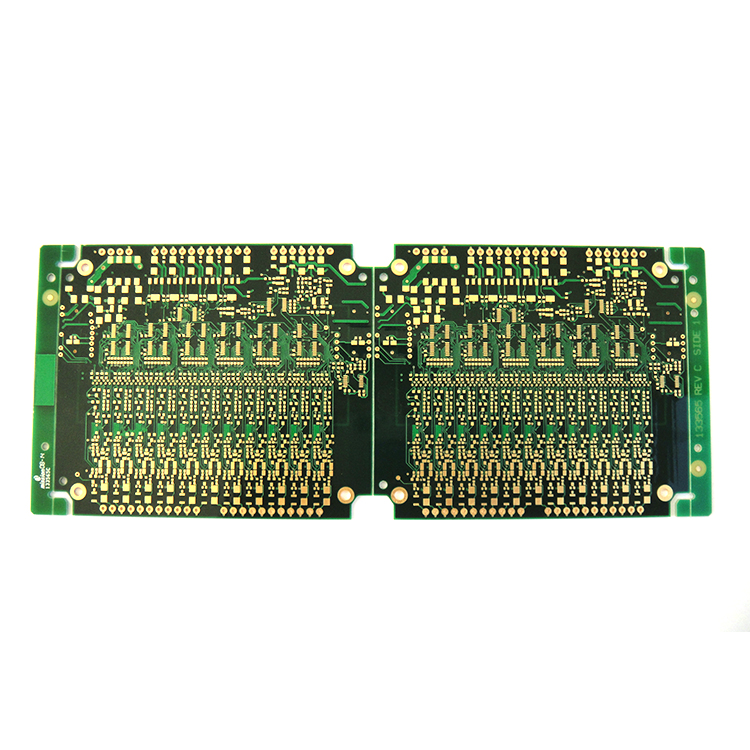

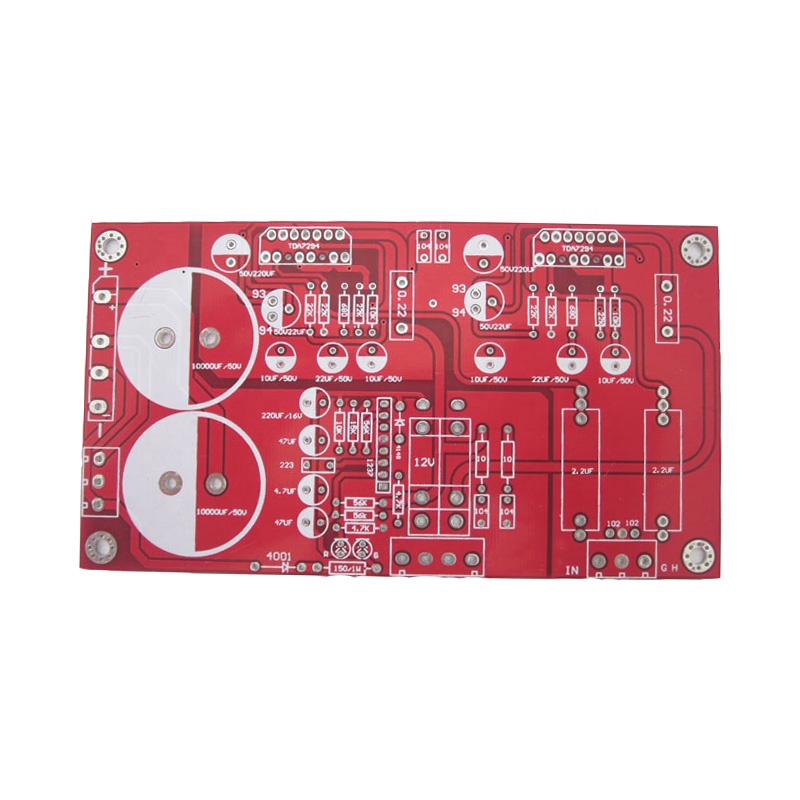

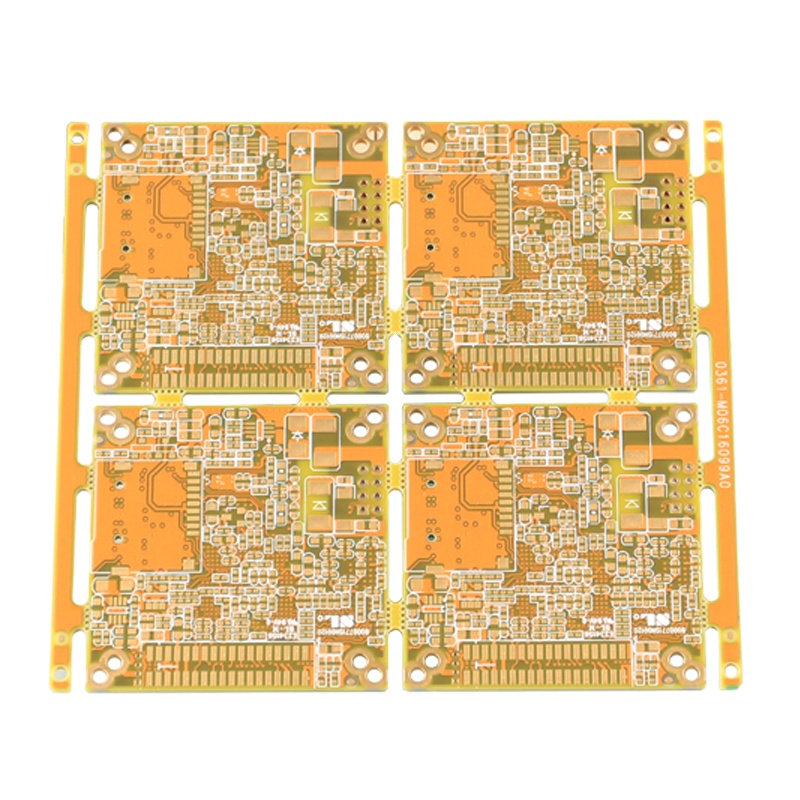

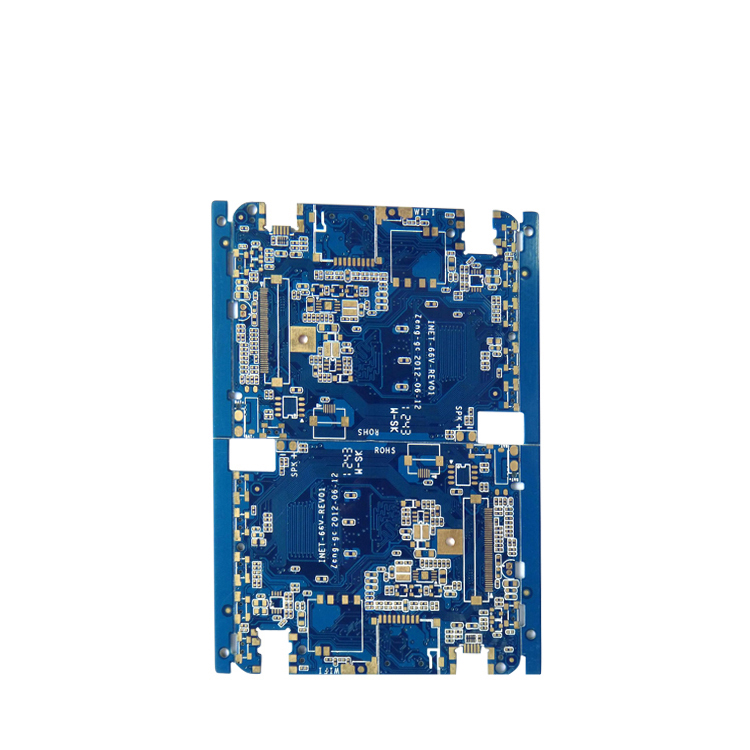

PCB Board Printed Circuit Board PCB Fabrication PCB Circuit Board Factory

¥ 0.00Buy now

-

China Electronic Custom 1.6mm FR4 PCB, PCB Circuit Board HDI PCB manufacturer

¥ 0.00Buy now

-

China Manufacture Custom PCB Circuit Board and PCB Assembly

¥ 0.00Buy now

-

Multilayer PCB Board Manufacturer China Circuit Board Assembly PCBA custom pcb

¥ 0.00Buy now

-

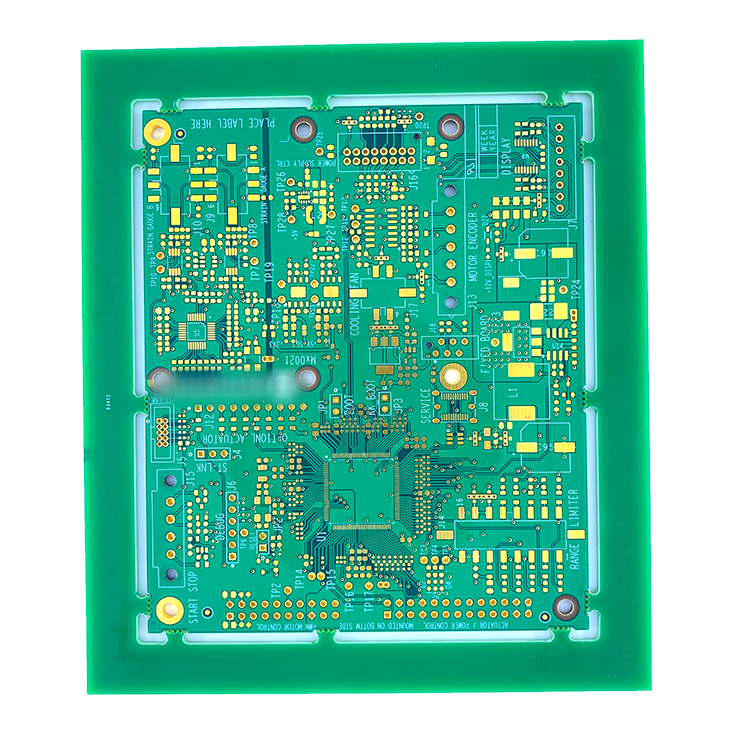

High quality bom smt PCBA service PCB Assembly 94v0 FR4 High TG Multilayer HDI PCB Board Manufacturer

¥ 0.00Buy now

-

Pcb Boards Pcb Multilayer PCB Board Manufacturer Electronic Pcb Printed Circuit Boards Pcb Factory

¥ 0.00Buy now

-

Oem Pcb Prototype Assembly Service Circuit Board Pcba Motherboard Electronic Industrial Control Board Pcba Manufacturing

¥ 0.00Buy now

-

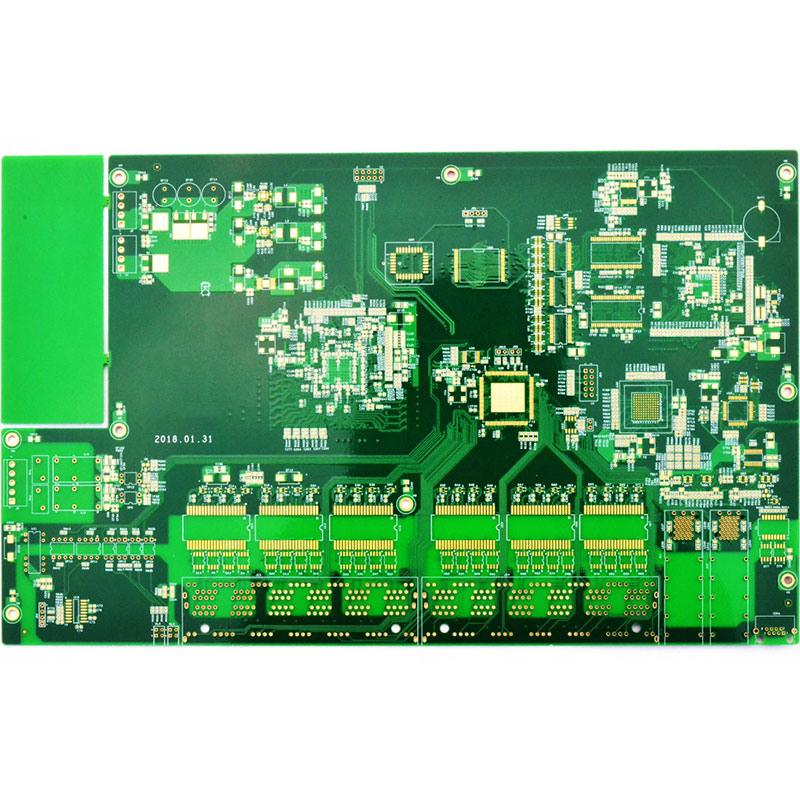

4 Layer PCB Manufacturing PCBA Prototype cheap price PCB Manufacturer in China

¥ 0.00Buy now

| Item | Manufacturing capability |

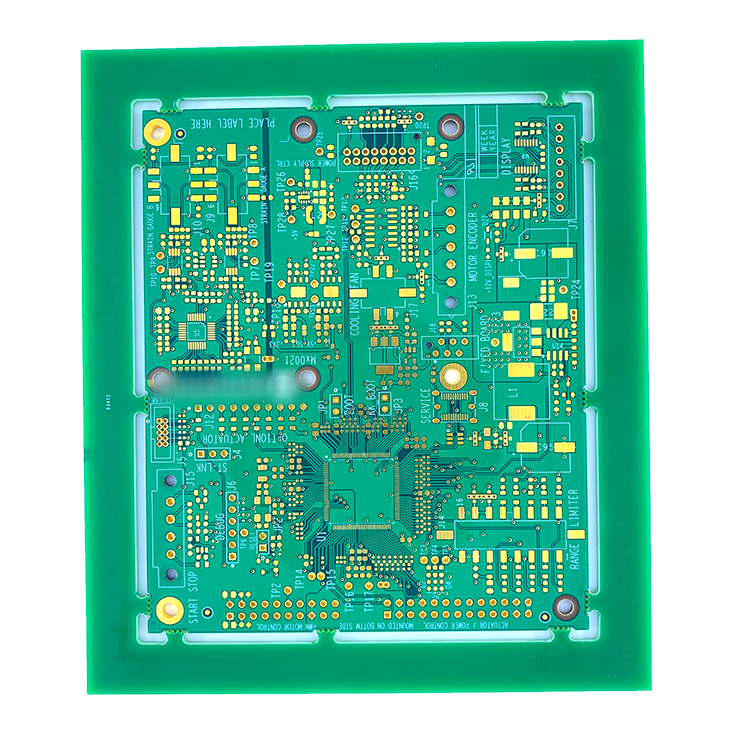

| PCB Layers | 1-64 layers |

| Quality grade | IPC Class 2/ IPC Class 3 |

| Laminate/Base material | FR4/High TG/ PTFE/ S1141/Ceramic PCB/ Polyimide/ FR406/ IT180A/ Isola-FR408HR/ Rogers/ Taconic/ Arlon/ Halogen free etc |

| Brand of laminate | Kingboard/ ITEQ/ Shengyi/Nanya/Isola/ TUC/ SYL/ Arlon/ Nelco/ Tacnoic/ Hitachi/ Rogers etc |

| High tempature material | Normal Tg: Shengyi S1141/KB6160/Huazhen H140(not suitable for lead free process) Middle TG: For HDI,multilayers: SY S1000-2/ITEQIT158/HuazhengH150/TU-662/SY S1150G/HuazhenghH150HF/H160HF High TG:For thick copper,high layers: SY S1000-2/ITEQIT 180A/HuazhengH170/Isola:FR408R/370HR/TU-752/SY S1165 |

| High frequency circuit board material | Rogers/Arlon/ Taconic/SY SCGA-500/S7136/HuazhengH500 |

| High speed PCB Material | SY S7439/ TU-872 SLK/ Isola:I-speed, I-Tera@MT40/Huazheng:H175/H180/H380 |

| Ink | Taiyo ink, Kuangshun, Rongda, S.M Materials |

| Heat conductivity for Alu.Boards | 1.0 |

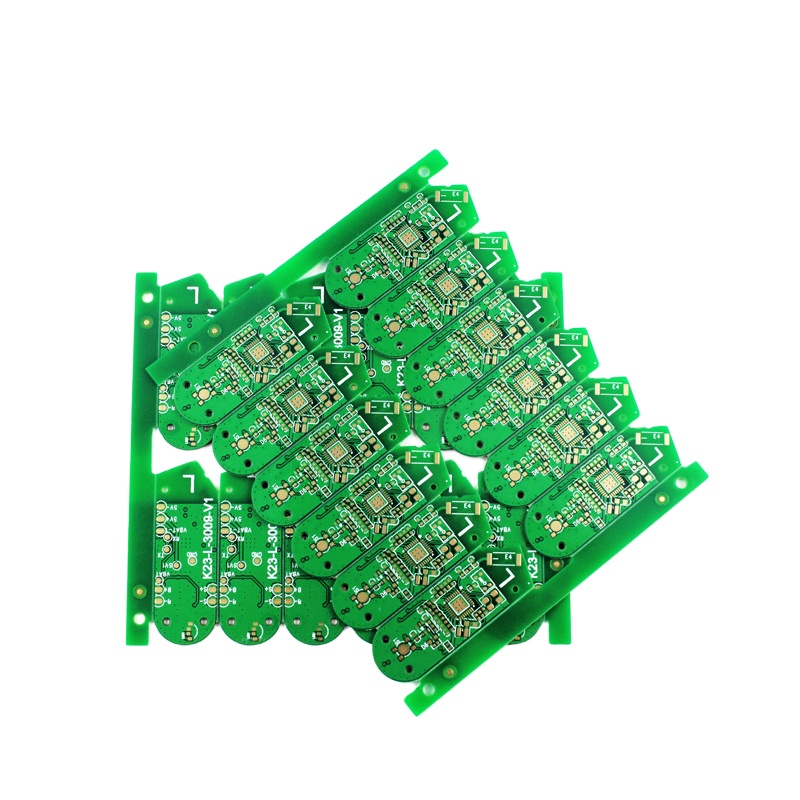

| PCB type and services | Rigid PCB, Flexible PCB, Rigid- flex pcb, HDI pcb, FR4 PCB, High TG PCB, Aluminum PCB, Metal core PCB, Impedance PCB,Multilayer PCB |

| Board size(Max) | 600*800MM |

| Board thickness | 0.1--8mm |

| Board thickness tolerance | ±0.1mm/±10% |

| Min base copper thickness | Outer layer:1/3oz(12um)--10oz Inner layer:1/2oz--6oz |

| Max finished copper thickness | 6oz |

| Min mechanical drilling hole zise | 6 mil(0.15mm) |

| Min lase drilling hole size | 3mil(0.075mm) |

| Min CNC Drilling hole size | 6mil(0.15mm) |

| Hole wall roughness(Max) | 1.5mil |

| Min trace width/spacing(inner layer) | 2/2mil(outer layer:1/3oz, inner layer:1/2oz) base copper |

| Min trace width/spacing(outer layer) | 2.5/2.5mil base copper |

| Min space between hole to inner layer conductor | 6 mil |

| Min space between hole to outer layer conductor | 6 mil |

| Min annular ring for via | 3 mil |

| Min annular ring for component hole | 5 mil |

| Min BGA diameter | 8 mil |

| Min BGA pitch | 0.4mm |

| Min finished hole size | 0.15mm(CNC)/0.1mm( Laser) |

| Half hole diameter | Minimum half Diameter:1mm, Half hole is a special technology, so half holediameter would be larger than 1mm |

| Hole wall copper thickness(Thinnest) | ≥0.7mil |

| Hole wall copper thickness (Average) | ≥0.8mil |

| Min Air Gap | 0.07mm(3mil) |

| Max aspect ratos | 20:01 |

| Min soldermask bridge width | 3mil(0.075mm) |

| Soldermask/circuit processing | Film/LDI |

| Min thickness for insulating layer | 2 mil |

| Max PTH(Round hole) | 8mm |

| Max.PTH(Round slot holes) | 6--10mm |

| PTH Deviation(Width) | ±4mil |

| PTH Deviation(Length) | ±5mil |

| NPTH Deviation | ±2mil |

| NPTH Deviation(Width) | ±3mil |

| NPTH Deviation(Length) | ±4mil |

| Hole position deviation | ±3mil |

| Character Types | Serial number/Barcode/QR code |

| Distance between Trace and Outline | ≥0.3mm(12mil), Ship as individual boards:Distance between Trace and outline ≥ 0.3mm, Ship as Panlized boards with V-cut:Distance between Trace and V-cut ≥0.4mm |

| Panelization without spacing | 0mm, ship as panelized boards and the space between boards is 0mm |

| Panelization with spacing | 1.6mm, make sure the spacing between boards shoule be ≥1.6mm, otherwise it will be hard to process routing |

| Surface finishing | OSP/HASL/Hasl lead free, Immersion gold,immersion silver,immersion Tin, ENEPIG, Golden finger+Hasl, ENIG+OSP,ENIG+Golden finger etc |

| Soldermask colors | Green, Red, White, Black, Blue, Yellow etc |

| Silkscreen colors | White, Black, Yellow etc |

| Electrical testing | Flying probe test, E-test |

| Other test | X-ray, AOI, Impedance control test, Solderability test etc |

| Profile | 1. CNC Routing(±0.1mm) 2. CNC V-cut(±0.05mm) 3. Bevelling |

| Special capabilities | Gold finger, blind and burried hole, semi-hole, plated board edge, via in pad, non-conductive resin plug hole, coil pcb, impedance control PCB etc. |

Company

Home

PCB Fabrication

PCB Assembly

Components Sourcing

Contact Us

Contacts

Tel: +8615889594075

www.pcba-boards.com

Email: sales@pcba-board.com

Whatsapp: +8615889694075